Polywood: Pioneering PVC Path, Saving Millions Of Trees

Polywood: Pioneering PVC Path, Saving Millions Of Trees

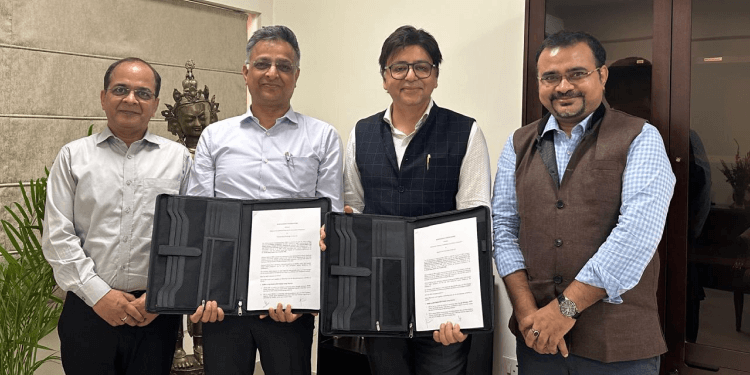

Dhabriya Polywood listed on the Bombay Stock Exchange’s SME platform recently. After ringing the opening bell Digvijay Dhabriya, the chairman and managing director of Polywood, said, “We believe that the listing will enhance our corporate image and visibility of brand name in the country. Our company will receive the benefits from listing of equity shares on the SME platform of BSE. We are extremely delighted for such an overwhelming response and faith in our organization from our investors who have invested.”

The issue got oversubscribed by 1.65 times and the company raised Rs 3.3 crore for future expansion of capacity, brand promotion and network expansion.

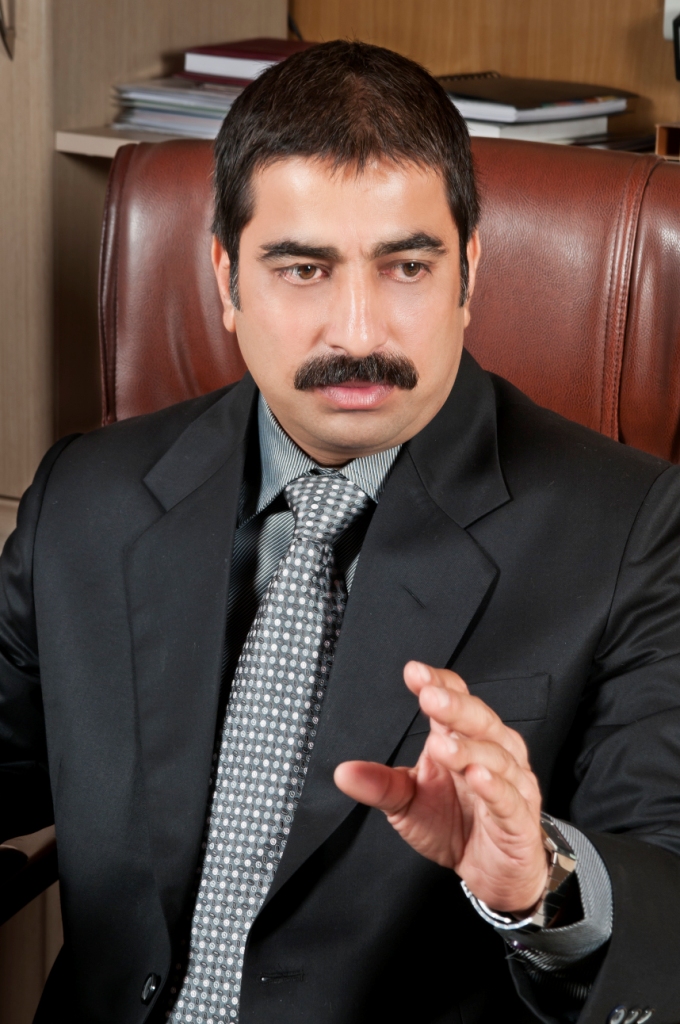

The milestone moment provides a vantage point to look at the journey that Mr. Dhabriya treaded about two decades ago with just Rs 3 lakhs seed money.’Ban plastic movement’ had gained some momentum in the past but the concerns were superficial as the critics were missing the woods for the tree, says Mr. Dhabriya, reflecting on the myopic vision of some of the known environmental experts.

Mr. Dhabriya, a post graduate in Plastic Engineering from Central Institute of Plastics Engineering & Testing (CIPET), Chennai, is not making any unfounded claims. After his studies, he worked for a few years with reputed organizations such as Garware, Varroc Engineering, Polycon Group. But he found out that his true calling was elsewhere.

“My father, who is no more with us was an environmentalist and a remote sensing expert. His motto in life was to save trees and he had contributed immensely towards preserving nature. He has been the inspiration for all of us to work towards the betterment of the human race by saving natural resources. His values have been the motto of our lives and we have reached so far following his footsteps,” said Mr. Dhabriya in an interview with Business Rankers.

Armed with a post-graduate degree in plastic engineering and a dream to save trees, Mr. Dhabriya started his own journey by setting up Dhabriya Agglomerates Pvt Ltd in the year 1992 which was later rechristened as Dhabriya Polywood Ltd. The company began commercial production of R-PVC Profiles with the brand name “Polywood”.

Today, the company is a name to reckon with in PVC and uPVC segments with a range of more than 35 products. Over the years, it has also stepped outside the state with not only manufacturing facilities but also a robust marketing footprint.”Every year, our products save about seven lakh trees. Studies suggest, 33% of green cover is required for a normal living but what we have today is not more than 8%. In the last 18 years , Polywood has created a lot of awareness about use of PVC Profiles, which was only confined to European countries earlier,” said Mr. Dhabriya.

Currently, Polywood has strengthened its portfolio of products that can replace wooden doors, windows, ceiling panels and a host of items where wood is used. Secondly, the products are aesthetically contemporary, classy, colorful and more importantly durable. Mr. Dhabriya says that even after the products’ life-cycle of 30-40 years, these products can be recycled into new use which is not the case with wood.

Moreover, in a world where time is precious, PVC and uPVC products come in handy. These products manufactured in the factory needs to be fitted or mounted or assembled helping the construction industry to roll out projects faster in a hassle-free manner.

The company ventured into uPVC segment in 2007 to meet the outdoor requirements. Outdoor windows and doors require strength to withstand the heat. uPVC products provide that protection. The Research and Redevelopment initiatives driven by Mr. Dhabriya himself have created a long line of outdoor products that can sustain any harsh weather conditions.

“We are engaged in continuous research and development with the help of our trained technical staff in the R&D wing and conduct in-house tests to keep a check on the quality of our products,” adds Mr. Dhabriya.

Like many businesses, innovation also plays a critical role in this industry and the group has made some path breaking strides adding new products unseen in the country before. “For the first time in India, we have introduced some exquisite products like PVC folding doors, PVC designer doors, PVC fencing, wood plastic composite panels and PVC aluminum composite panels,” says Mr. Dhabriya.

Expansion plans and also promotion of PVC and uPVC products are high on the priority list of the company. Today, it produces three lakh sq ft of uPVC windows per month and 600 metric tonnes of PVC products. It has recently put up a uPVC factory in Sitapura that produces 1 lakh sq. ft every month. It is also planning to add one more line for an additional 50,000 sq ft every month. It also has a manufacturing facility in Coimbatore.

Besides capacity expansion, Polywood is ramping up its Application Centre Network in the country with presence in Bangalore, Chennai, Cochin, Kolkata, Delhi and Jaipur. But Mr. Dhabriya said the company will upgrade Kolkata, Delhi and Jaipur application centres. The application centres provide customers information about the range of products, their application and installation and helps the company to reach closer to the customer base.

In 2007, the company initiated its first uPVC window manufacturing unit which comprised of just one fabrication line with a capacity of 55,000 sq ft per month.

In 2011, the firm doubled production capacity from 55,000 sqft to about 1,10,000 sq ft with the establishment of two lines. By 2014, the company further expanded its potential to establish two more lines. Currently, Polywood functions with 4 lines in Jaipur to fabricate uPVC windows and doors. Today, Dhabriya Polywood Ltd has six window fabrication lines in total which include two lines in Coimbatore and 4 lines in Jaipur, Rajasthan, generating a total manufacturing capacity of approximately 3,00,000 sq ft per month considering about 60-70% efficiency utilization in just one shift.

“The company intends to utilize the proceeds of the issue to meet the objectives of funding its expansion plans, setting up Polywood Application Centers in Rajasthan, meet the issue expenses and for the corporate purpose,” Mr. Dhabriya said at the time of listing.

Even though the construction industry last year went through a tough time owing to demand contraction, Polywood had posted a marginal profit.

But Mr. Dhabriya says, the growth is set to pick up after the new momentum being generated by the measures the new NDA government is taking to spur economic activity in the country.

“In 2013-14, Polywood posted a profit of Rs 70 crore registering a marginal growth over the revenues of Rs 67 crore in 2012-13. But given the current momentum in the economy, we expect a revenue growth of 20-30% in the coming year,” says Mr. Dhabriya.